Menu

Part Consolidation and Internal Features

- Additive Manufacturing, Case Study

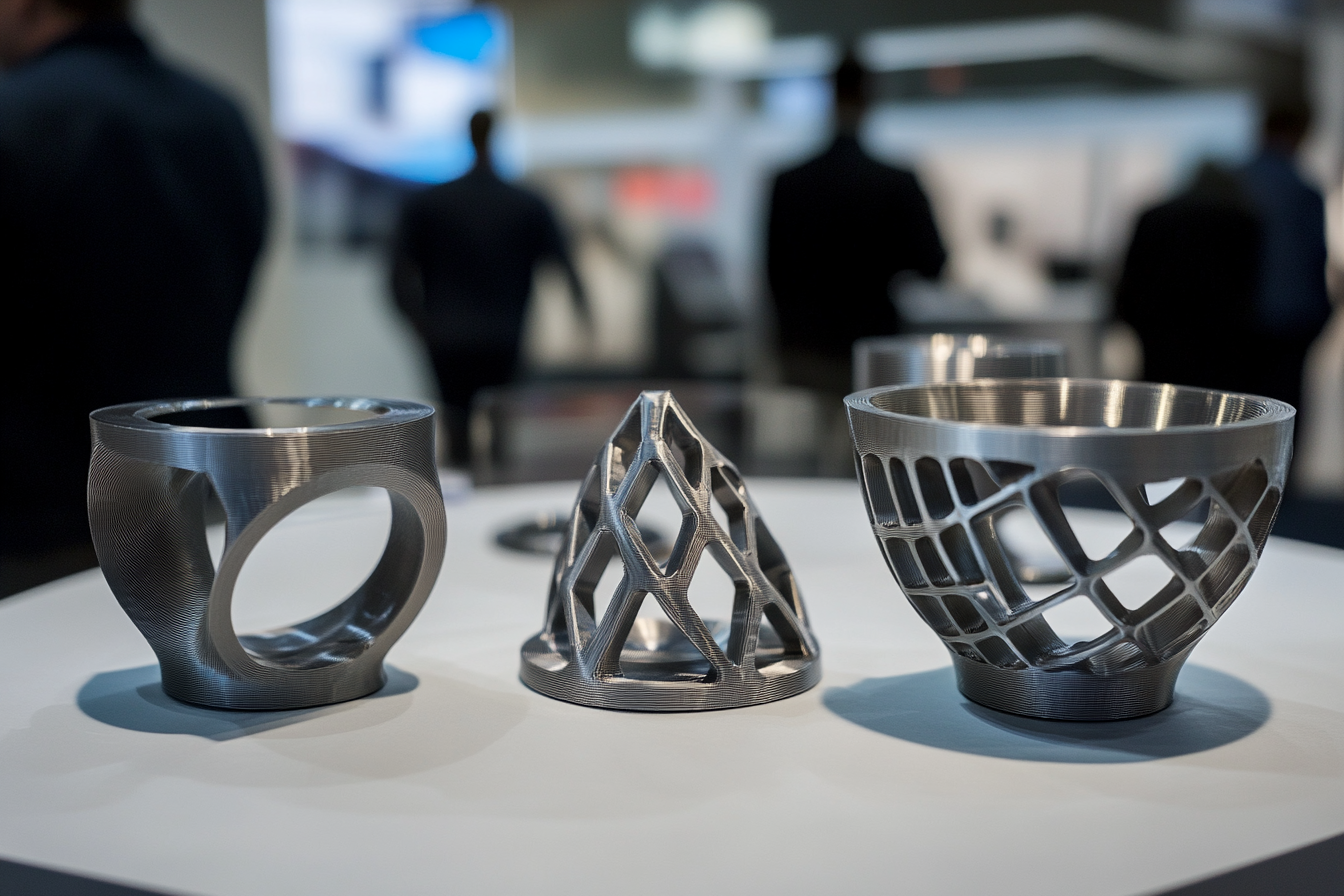

Additive design allows multiple parts to be merged into one. Markforged points out that 3D printing can embed complex channels and cavities inside a single component. For example, instead of assembling many straight tubes into a block, engineers can print a one-piece manifold with internal ducts. This consolidation eliminates fasteners and seams, cutting assembly work and potential leak paths. Good design for additive “minimizes the number of parts,” Markforged notes – this reduces error, scrap, and lead time.

Formlabs SLA can achieve similar integration. For instance, PSYONIC initially printed each finger of their prosthetic hand separately but later switched to printing mold halves as one assembly for stronger, more reliable parts. In many industries, 3D printing encourages revisiting part families: what used to be multiple injection-molded or machined pieces can often become a single 3D-printed assembly, greatly simplifying the bill of materials.

ref: Markforged